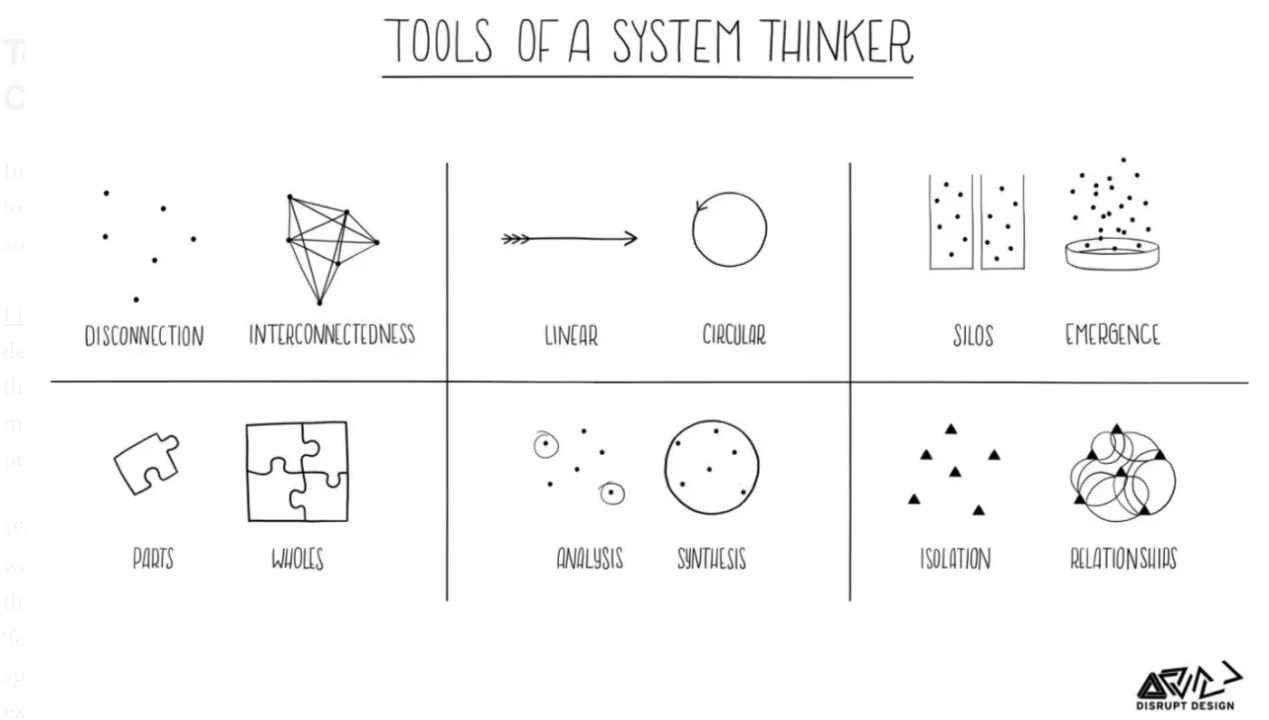

The lack of system thinking across the FM and construction sector is a primary cause of rampant economic and environmental waste. Until system thinking is understood and adopted on a widespread basis, there is little likelihood of measurable improvement.

What is system thinking? – Simple, it’s the process of considering the whole and how the all the associated parts, people, actions, resources interrelate, and discovering ways of improvement.

Why does it matter? – The application of system thinking to facilities management (FM) and the AECOO sector, and associated tools and support processes, can consistently ensure the delivery of quality, sustainable outcomes, on time and on budget. (AECOO = Architecture, Engineering, Construction, Owners, Operators)

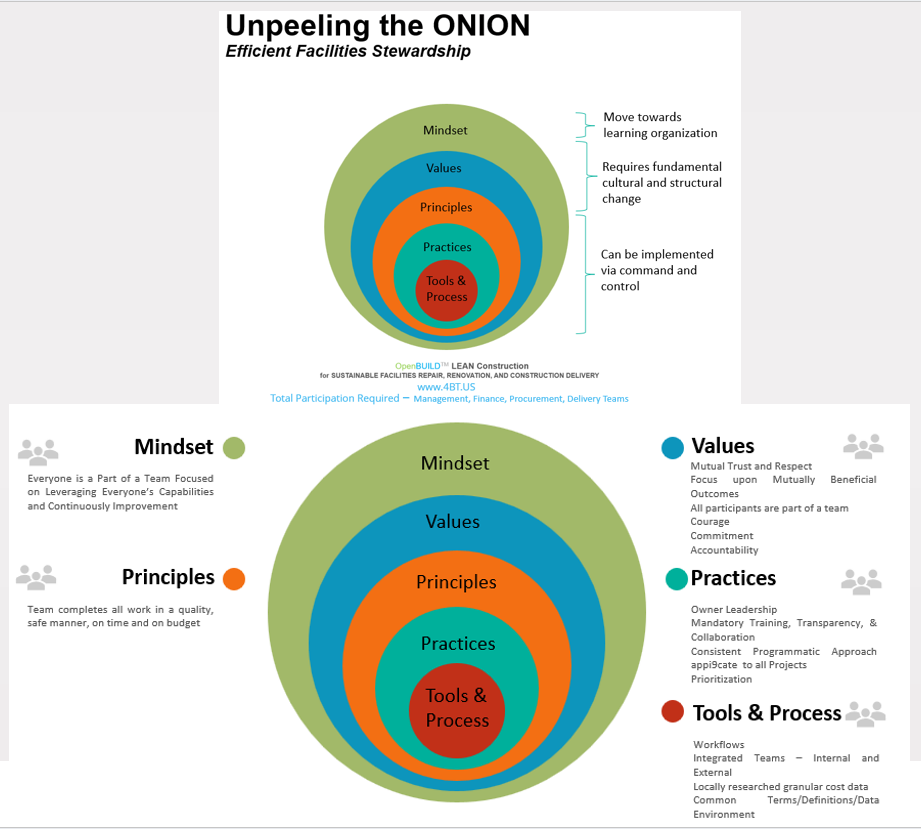

What are the barriers? – System thinking requires a fundamental change in mindset for current AECOO players. While the following may sound like “common sense”, the philosophies and concepts are rarely practiced. Care of People. – Innovation and improvement require that traditional adversaries find common ground. We all know that traditional planning, procurement, and project delivery practices are adversarial, and broken, yet we fail to address this basic issue. Owners must lead a change in mindset and provide a consistently safe, welcoming, and collaborative environment. Everyone involved also must enable those doing the work, those with hands-on knowledge, to contribute to solutions in innovative ways.

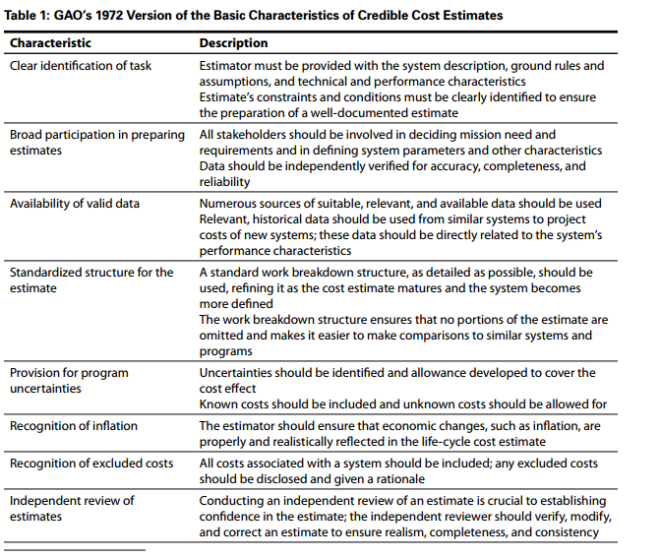

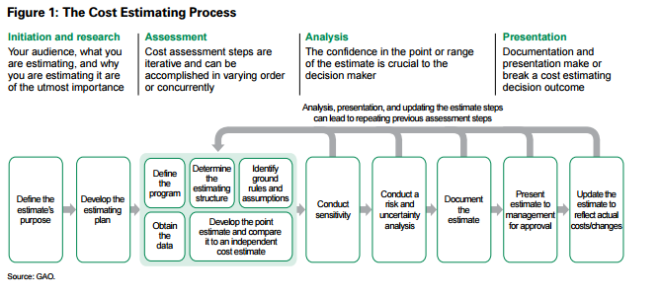

Improving construction cost estimating requires collaboration, transparency, and a robust process. An essential aspect is sharing objective, local market, granular labor, material, and equipment costs. Relying solely on contractor or subcontractor costs, especially lump sums without collaborating on a detailed Scope of Work (SOW), will not lead to verifiable construction costs.

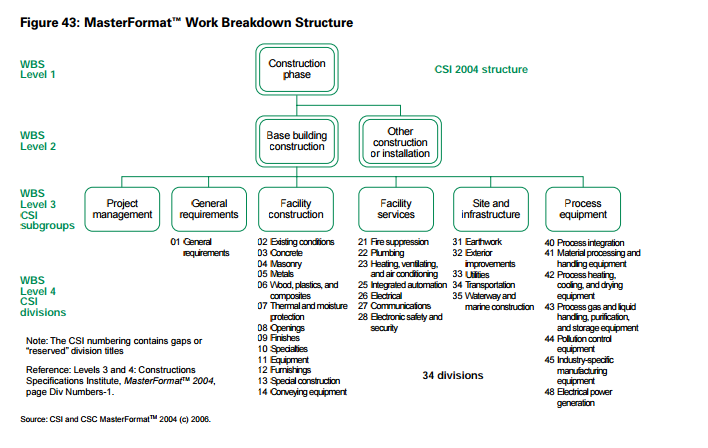

To efficiently share cost information, organize data in a standard architecture, such as expanded CSI MasterFormat, and use industry standard terms, definitions, and units of measure. Collaboration in the above manner allows disparate groups, including owners, A/E’s, builders, and procurement professionals, to focus on common goals.

Collaboration involves both giving and receiving help. It’s essential to remember that the process must include direct owner involvement. The excessive use of “consultants” will not enable an environment of true owner and design/builder collaboration that is mandatory for optimization of outcomes. Maintaining alignment among team members is challenging but essential.

4BT.us offers a useful resource for objective, verifiable, and current local market unit price books to help improve construction cost estimating. Check it out!

#costestimating #construction #estimating #verifiable #accurate #costdata #masterformat #csi #benchmark #standard