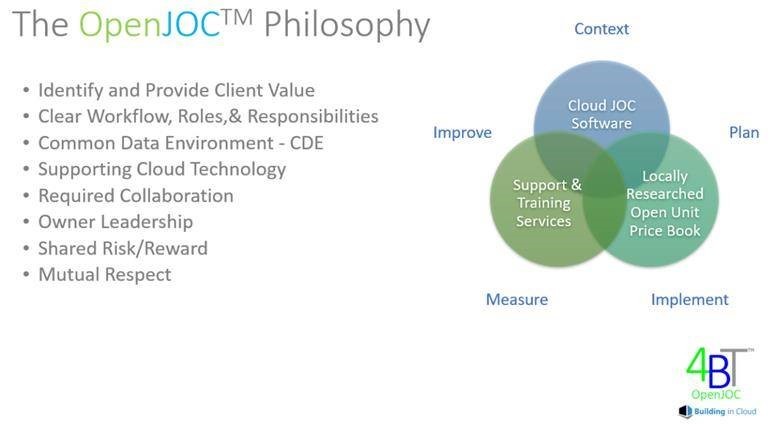

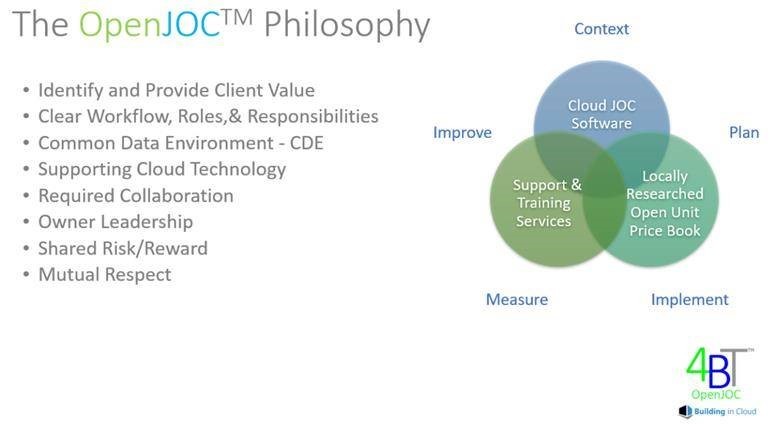

(2) Common Data Environment: A locally researched detailed unit price book, UPB, using common terms and definition, and organized using CSI MasterFormat 50 Division, is key to assuring mutual understanding of work scope and financial visibility/transparency.

(3) Document project needs/stages/issues/information in real-time: Nothing is more important to avoiding construction disputes than preparing solid, detailed, and contemporaneous documentation during the project. This is greatly aided by a cloud-based program/project/estimate/document management systems. All parties have appropriate access to the information they need. Furthermore, a full document management system assures that everyone is working on the same and current version of information. Documents are checked-in and checked-out, just like a library, and only persons with appropriate permissions can edit them.

(4) Shared Risk/Reward, Mutual Trust/Respect, Long-term Relationships: When a problem comes up on a project, deal with it head-on, and do so in an open, shared, manner without assigning blame. Seek solutions from appropriate team members. Document and learn from the mistakes and adjust procedures appropriately. This is what collaborative and continuous improvement… and LEAN… is all about.

(5) Require Initial and Ongoing Training. Require Collaboration. Use all the tools and services at your disposal. All participants must be required to attend initial and ongoing training. Collaboration mus be required of all participants. And lastly, all the tools, training, and services to assure consistent success are readily at your disposal. Use them!