- Identifying and prioritizing key requirements (personnel, assets, methods, timelines)

- Defining and developing processes that support positive outcomes

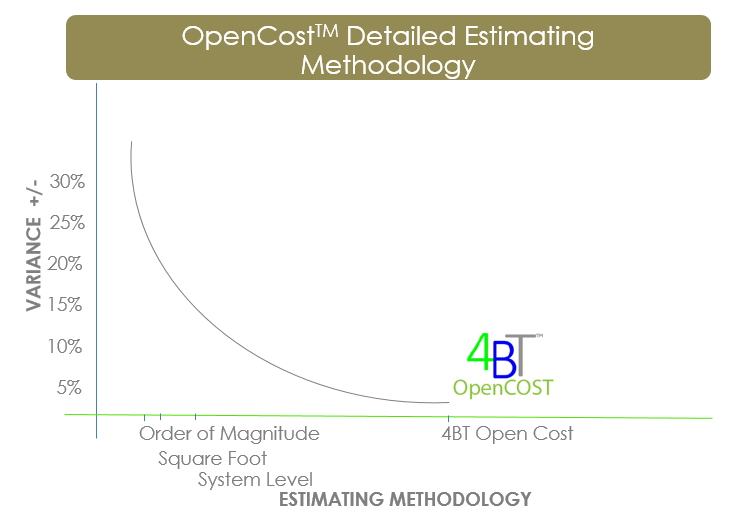

- Identifying and adhering to a common data environment including a locally researched, independent, and objective unit price book

- Implementing workflows and processes consistently and leveraging purpose-built JOC cloud technology

LEAN Procurement via Collaborative Job Order Contracting required teaming throughout the life-cycle of the project. Procurement, engineering, and building uses are part of the project from concept through warranty.

The Benefits of LEAN Procurement via Collaborative Job Order Contracting

- Project sequencing optimization – Process is well defined to assure that information is created and shared at the right time

- Information-asset alignment & transparency – Classification of project information is standardized (MasterFormat) and aligned with user requirements

- Waste reduction – Shared information environment and defined LEAN construction processes mitigate miscommunication, change orders, and legal disputes

- Projects timelines are shortened.

- Quality & Satisfaction are enhanced

- Reduced complexity via standardized processes, data formats, and information sharing among varied areas of expertise – Procurement is complex and difficult without the support of varied competencies. Challenging traditional, ingrained, and inefficient processes in favor of collaborative LEAN methods improves productivity through the use of openly-shared common information.

]

]

Owners must be competent and provide LEADERSHIP (Click to read 2017 NIBS Article)

The success LEAN Procurement via Collaborative Job Order Contracting and attainment of available benefits requires that real property owners/facilities management be competent and provide leadership. The capability of the Owner team and the maturity of the associated facilities management systems must be at a prerequisite level.

Owners must view service providers as part of their team and operate within an atmosphere of mutual respect and trust.

Owners can work with JOC consultants to structure JOC Programs, however, JOC consultants should NOT be managing the JOC Program. JOC programs are collaborative service supply models and require equal participation of all stakeholders in terms of roles, responsibilities, information creation/sharing, monitoring, etc.

The JOC collaborative construction service supply model relies upon an integrated team with a focus upon attaining positive outcomes, and a shared approach to problem solving and challenges.

Learn more…

Key characteristics of

Key characteristics of

Job Order Contract Staffing should include skilled owners and construction contractors, and the limited use of JOC consultants.

Job Order Contract Staffing should include skilled owners and construction contractors, and the limited use of JOC consultants.

www.4BT.US

www.4BT.US

Define Construction Procurement

Define Construction Procurement Define Construction Procurement

Define Construction Procurement