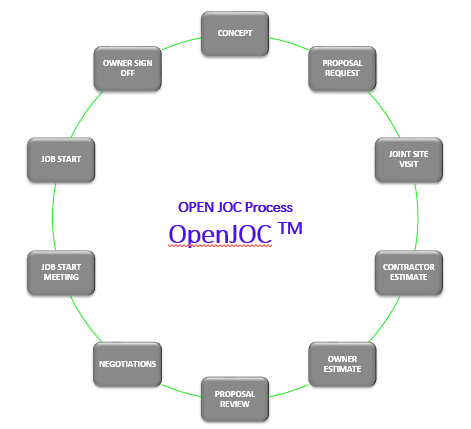

OpenJOC Job Order Contracting is a robust LEAN construction delivery method that provides best value, on-demand repair, renovation, and construction services to the benefits of all participants… owners, contractors, subcontractors, building users, and oversight groups. All job order contracting is not that same, and its up to you to assure you provide a collaborative, transparent, and compliant solution. OpenJOC job order contract provides the tools, processes, and training to do just that!

Learn more about… Requirements, OpenJOC Job Order Contracting (JOC) Information Life-Cycle, Core Value Proposition, Activities & Tools, Available Support, Operations Manuals/Execution Guides, Actionable Detailed and Locally Research Cost Data, and Change Management.

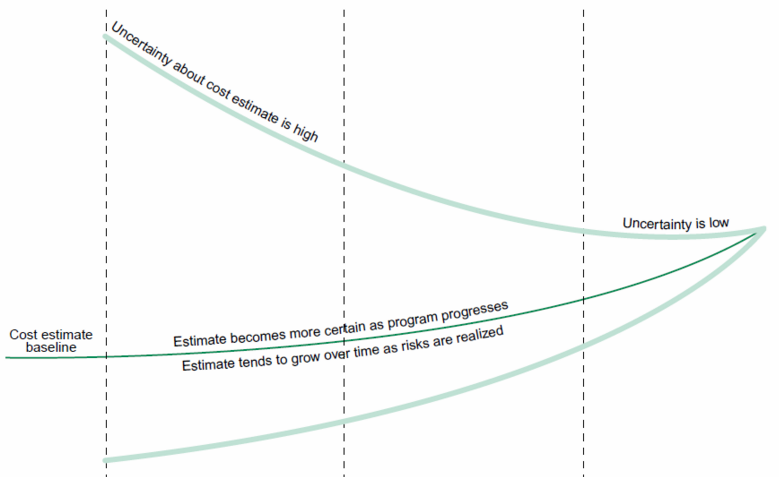

Local construction cost data is critical to owners, builders, and architects. Using area cost factors or “localization factors” simply doesn’t work as it doesn’t account for changes in crews, actual labor variations, and so on.

Local construction cost data is critical to owners, builders, and architects. Using area cost factors or “localization factors” simply doesn’t work as it doesn’t account for changes in crews, actual labor variations, and so on.

LEAN Pre-Construction services considerations significantly improve outcomes.

LEAN Pre-Construction services considerations significantly improve outcomes.

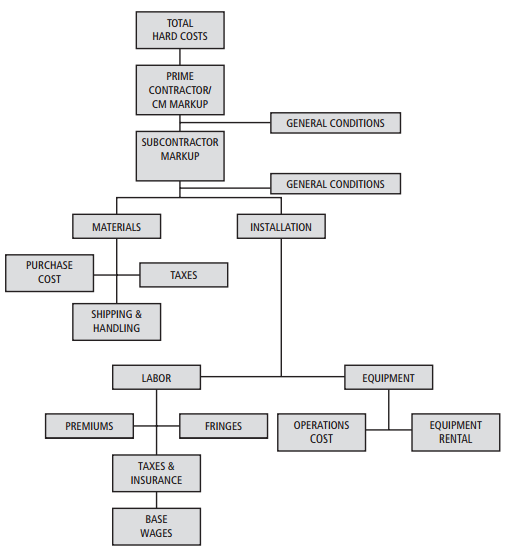

helps drive better outcomes for owners, contractors, and subcontractors and better assure financial transparency as well as fiduciary responsibility.

helps drive better outcomes for owners, contractors, and subcontractors and better assure financial transparency as well as fiduciary responsibility.